Vacuum Packaging and Marinating Systems

Innovative vacuum packaging and marinating technology for the kitchens of the future.

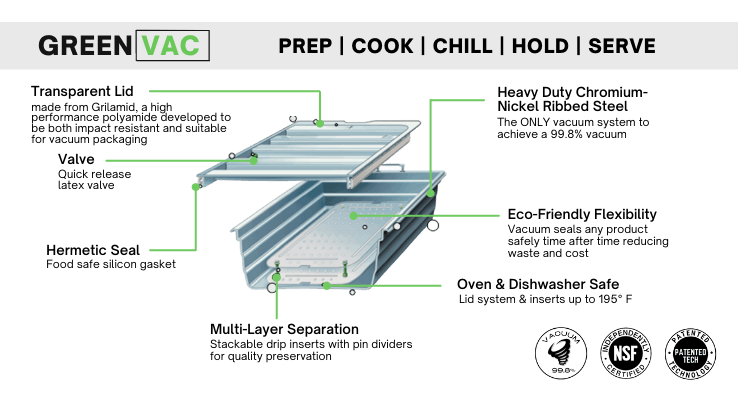

GreenVAC is an environmentally friendly reusable vacuum packaging system specially manufactured to not collapse under an industry best 99.8% vacuum!

The GreenVAC multi-purpose pan revolutionizes the food waste & food prep in foodservice.

This Vac-pan system is designed to hold a full vacuum (up to 99.8). This means you can bulk prep/purchase because it keeps fresh and freshly cooked foods fresh for 2-3 weeks when stored at 41f. Multiple savings in food cost & labor, all while keeping your kitchens teams ready for the unexpected.

Benefits include….

- Increased shelf life of fresh & freshly cooked food products

- Bulk prep once a week vs every day

- Cook, chill, store/transport, retherm & serve all in the same pan

- Marinate, brine, tenderize, infuse & pickle in minutes

- Multiple sizes - an be used in any size kitchen operation

GreenVAC Solutions Virtual Presentations

Learn how GreenVAC Multi-Purpose Pans can help you save time and money.

K-12 School Foodservice Demo

Catering / Event Demo

Rapid Marinating and Brining

As air is removed and pressure lowers in the GreenVAC CombiPan, the pores of the protein open allowing liquids to easily penetrate into the product. Once the valve is released, the pores close and further soak in the marinade like a sponge. This makes bulk marinating proteins much faster (minutes) and with much better results than traditional methods of marinating & brining.

Tenderizing

By lowering the air pressure, the fibers of the meat begin to naturally stretch. Once a full vacuum is achieved the fibers of the protein will be held in a stretched state until the valve is released. Once pressure is released, the protein goes back into its original form. Therefore, no need to whack, jaccard, hammer or needle. Tenderizing in the GreenVAC CombiPan turns a cheaper cut of meat into a tender piece and/or can change the texture.

Infusing and Pickling

The cells walls of fruit & vegetables contain pockets of air and water. As outside pressure decreases during vacuum sealing, these pockets rise up and eventually pop. The pockets then collapse under the weight of low pressure and are rapidly replaced with the pickling and/or infusing liquid. Therefore significantly reducing pickling time and/or compressing flavored liquids into the cell structure of these types of products.

Guaranteed Durability

GreenVAC Vacuum Packaging Systems are manufactured from 1.2 mm (17 gauge) and 1.5 mm (18 gauge) chromium-nickel steel VS. Standard gastronorm containers at just 0.5 mm thick (20 gauge) and manufactured from often softer metals.

Its reinforced design enables products sensitive to pressure, such as salad and berries, to be directly vacuum packaged and conveniently stored.

The transparent lids are made from a material called Grilamid, which is a high performance polyamide developed and manufactured in Switzerland. Grilamid is both impact-resistant and suitable for vacuum packaging.

All products are able to withstand dishwasher cleaning cycles at temperatures of up to 195F time and time again.